- Tel:+027-81821900

- Fax:+027-81822580

- After-Sale Service Hotline:400-032-686

- Address: No.8 Qingshui Road,Jinyin lake, Dongxihu District, Wuhan City

WeChat official account

1.Introduction of product function

l Start and idle speed closed loop control

l Acceleration/deceleration transition working condition control

l National IV emission standards

l Self-adaptation control for “High temperature, high cold, plateau” environment

l OBDⅡ diagnostic strategy function

l Closed-loop self-learning for fuel oil

l Oxygen sensor heating control

l Exhaust temperature model control

l Vehicle cooling fan control

2. Introduction of product performance

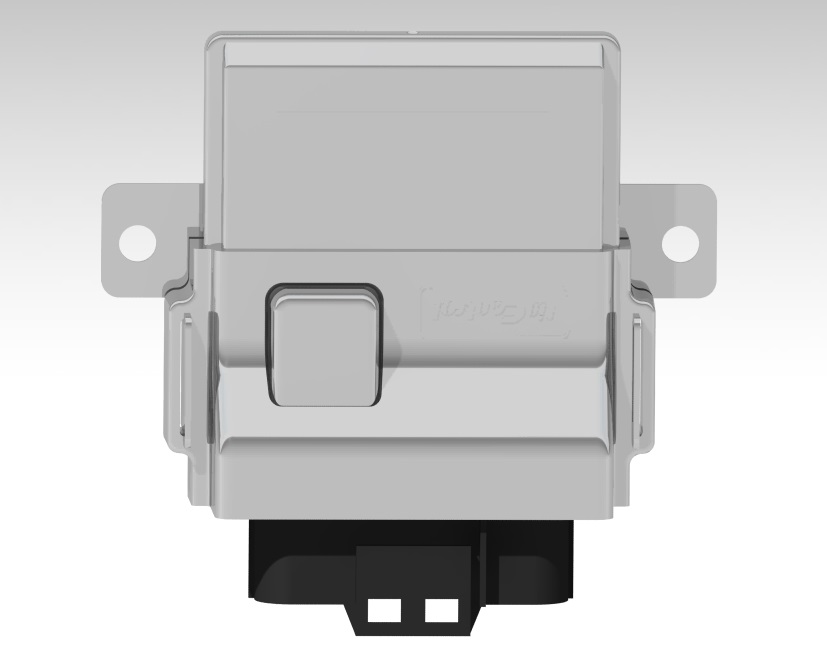

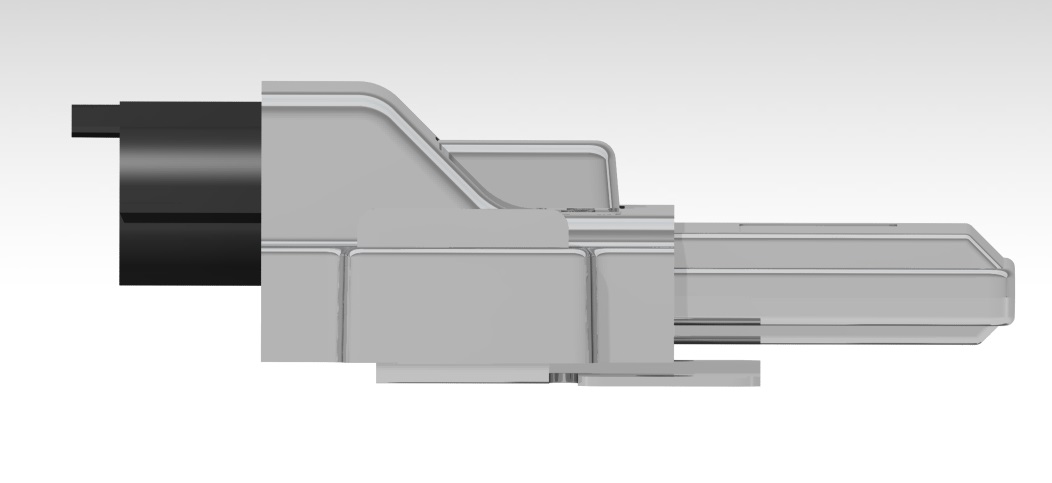

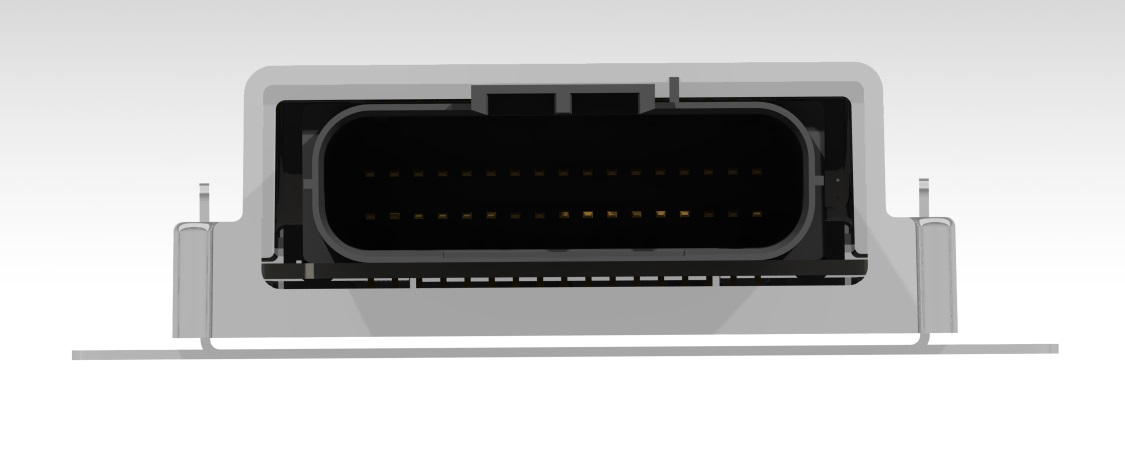

l High-performance 16/32 microcontroller (MCU) has been adopted for the ECU hardware: wide working temperature range; fast computational speed; large program and data memory; flexible I/O port

l The integrated drive IC with diagnosis function has been adopted for the ECU drive circuit: the open circuit and short circuit detection of drive output circuit can be achieved.

l Software adopts the modular C programming language and the FLASH self-programming technology: the modification of calibration data in the program storage can be realized.

3. Advantages of product solution

l The closed-loop control can effectively reduce emission, satisfying the stricter emission regulation (GB14622-2016)

l The optimization of ignition angle under various working conditions can improve the overall performance of the engine.

l The combustion efficiency can be improved and the fuel consumption can be reduced.

l The cold start and low-temperature driving performance can be improved.

l The stability of idling can be improved.

l The consistency of the working process for the engine can be improved.

l The application range of engine can be extended.

4. Product application scope

l It is applicable to motorcycle engine with displacement 100cc ~ 500cc single cylinder/twin cylinder (synchronous)

l The carriable vehicles include ATV, UTV, tricycles, straddle bicycles, scooters and bent beam vehicles.

WeChat official account